Materials + Kits

Good boats are built with good materials.

Choosing a kit supplier (All kits are not created equal)

Understanding what to expect in a small boat kit and how quality benefits you will help put saving a few dollars in perspective. If you put a price on the time you will spend building your boat, buying the best materials will be a small part of your investment and a big part of your pride and satisfaction.

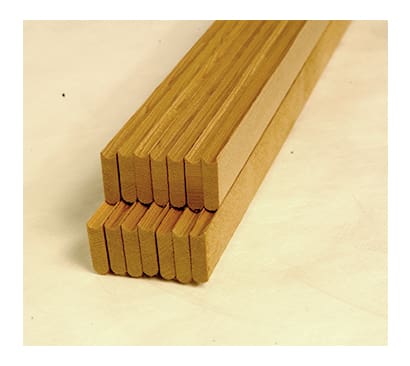

Planking – What to look for?

Planking – What to look for?

In the past 45 years, we have shipped thousands of feet of premium custom-milled cedar strips to our customers all over the world. However, it is becoming increasingly difficult to keep this standard up. We’ve known for years that some varieties of wood used in boat building, like western red cedar and eastern white cedar, were a limited resource. Shipping these woods from Canada around the world is becoming unsustainable due to both availability and shipping costs, and the impact on the environment can’t be ignored.

Considering that only part of the hull requires full-length strips, we are now including some shorter strips in the bundles we send. When you open your bundle of planking you will see that you have enough long strips to plank the length of your boat where full length is required. There will also be some bundles of shorter strips that can be used where full length is not required. This will require some planning on your part to create the colour pattern you desire.

There are few methods to join short planks:

1. A simple butt joint is all that is needed in most places where the plank does not have a twist to it. We recommend staggering the joints. Make the join between the station molds so you are not tempted to use too many staples, it also allows you to clamp on the inside and outside to get a good fit. See page 124 of Canoecraft for more info.

2. Making a scarf joint is another possibility but it can be tricky to cut and line up. It is hard to cut an accurate scarf joint that you can put back together, and depending on the overlap the plank could be too thick or too thin. A diagonal scarf is worth considering because it is easier to cut and line up although will be more visible. See Kayakcraft page 49 for more.

We have always encouraged people to make their own planking using wood that is available locally even if it means cutting around knots in less than perfect wood and joining shorter planks. Joining strips is an effective and environmentally sound approach.

Accurately machined bead and cove edges.

The way the plank edges fit together have everything to do with the pleasure factor in planking your hull. Poorly machined edges create all kinds of extra work and annoying complications.

When the bead or cove is machined off center, there will be a step between each plank. The high plank will have to be shaped down to meet the low plank and the process repeated again on the inside of the hull. Not only does this add considerably to the dusty part of your building time, reducing the thickness of the plank also reduces the stiffness of the hull.

The depth of the cove is critical. The ideal depth will show the edges being slightly flat, about 1/64” wide of equal width on both edges. If the flat is equal on both sides, the cove is centered. If the cove is to shallow, there will be a crack on both sides of the joint. While the crack doesn’t extend all the way through, the crack must be filled before applying the fiberglass and epoxy resin; if not filled, air will be trapped in the void.

When the cove is machined too deep, you will see both edges ending thin like a feather. It is impossible to handle this plank without damaging the edges. When the edge breaks off, extra steps are added to the project. The biggest problem is not having to fill the voids but cleaning splinters out of the cove before installing the next plank. Leaving the splinters in will take the project to another level of unnecessary problem solving.

Inconsistent machining will allow the planks to fit in some places but leave the joint open and loose in other areas. It may look secure until the staples are removed to release the planking from the mold and the joint opens up. The problem is fixable but it is a learning opportunity best avoided.

What Epoxy do you recommend?

The epoxy resin is what holds a strip-planked/epoxy hull together; it is the main component in the structure of the hull. The epoxy resin in a kit accounts for a significant portion of the total cost of the kit; including a cheap resin significantly reduces the cost of the kit but is that doing you a favor? While there are some places where you can compromise and reduce the cost of the building project, using less than the best epoxy resin is the last place you want to economize.

We have been using West® System epoxy for more than forty years and have complete faith in the quality and integrity of their products. They have consistently worked to make their epoxy system safer and easier to use and maintain. While there are many epoxy formulations, very few are engineered to be compatible with wood. We have tested several of the better epoxy resin systems but the West® System is still the only resin system we would recommend for safe, predictable results and being best suited to this type of construction.

What hardener do you recommend?

105 Resin / 207 Special Coating Hardener - Recommended where an exceptionally clear finish is needed to enhance the woods natural beauty. Designed to work well in cool, damp conditions without clouding. If your building environment is unpredictable, we recommend the 105/207 resin system. Each kayak or canoe requires about 2 gallons (or 2 'B' Packs) of resin/hardener for laying up the fiberglass. If you are building more than two canoes a "C" Pack is most economical.

What about Fibreglass cloth?

It is important to use a cloth that is compatible with the epoxy resin. To facilitate the glass fibers bonding to the resin, a finish or interface is applied to the fibers. There are a number of finishes available for specific resin systems. The finish on cloth designed for polyester resin must be dissolved by the styrene in the resin. Epoxy, being 100% solids has no solvent to dissolve the finish thus this cloth would be unsuitable for our use. This is the most common cloth available and the cheapest but the results for our purpose are questionable. When the glass fibers are not bonded to the resin, the peel strength is compromised and a less than clear finish is quite possible.

Packaging and shipping is also important. The cloth should be carefully rolled to avoid wrinkles. Hard creases in the cloth will not want to lie down and become a problem to deal with.